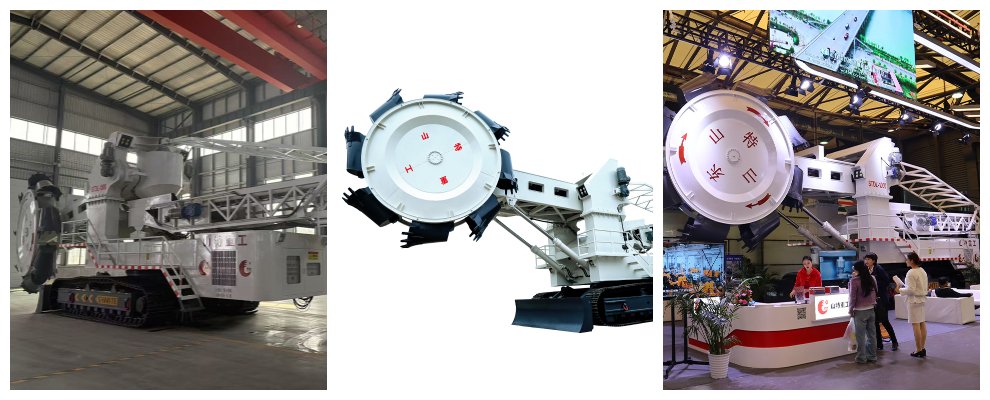

High Quality Port Bucket Wheel Excavator

Prodcut Advantages:

High efficiency: The bucket wheel machine has a strong loading capacity, which can load a large amount of materials at one time and transport them to the destination. Its loading and unloading speed is fast, can complete a large number of handling tasks in a short time, and significantly improve production efficiency. Wide range of applications: bucket wheel machine is not only suitable for large coal, ports and other logistics centers, but also suitable for construction sites, metallurgy, chemical industry and other industries handling and drying work. The adaptability is very wide.

Strong ability of continuous operation: bucket wheel machine adopts continuous operation mode without shutdown, which has greater advantages compared with traditional loading and unloading machinery.

Product Details

Product Introduction:

Operational Principle

The bucket-wheel excavator operates in stationary mode during material excavation, relying on the coordinated motion of its front-mounted rotating bucket wheel and the boom’s slewing action to continuously shear and load materials into the buckets. As the buckets ascend to a predetermined elevation during rotation, gravitational discharge directs materials onto the intake conveyor belt. These materials are subsequently routed through a hopper to the discharge conveyor system for final transfer to trucks or bulk transport systems. Upon completing a material layer, the machine advances or retracts its boom to excavate subsequent layers vertically downward. Layer thickness is regulated by the excavator’s linear displacement or boom extension, while excavation width correlates with slewing velocity. Mobility serves a secondary role, with primary emphasis on continuous excavation via the bucket wheel and material transport through conveyor systems.

Structural Configuration

The bucket-wheel excavator comprises six core subsystems: tracked undercarriage, slewing assembly, excavation mechanism, material handling system, electrical propulsion system, and hydraulic control system. Distinctive features include:

(1) Tracked Undercarriage System

Contemporary bucket-wheel excavators predominantly utilize crawler-based mobility systems, with select models employing walking mechanisms. Dual-track configurations are standard for medium/small units, while large-scale excavators adopt multi-track designs (triple/quadruple-track) to minimize ground pressure distribution.

(2) 360° Slewing Assembly

Incorporating a rotating superstructure and azimuth drive components, this system accommodates powerplants, transmission gear, control interfaces, and the operator cab. A slewing ring bearing enables full circumferential rotation of the superstructure about the vertical axis.

(3) Excavation Mechanism

Consists of the bucket-wheel assembly, articulated boom, elevation adjustment system, and drive train. The bucket wheel—a circumferential array of evenly spaced digging buckets—is mounted at the boom’s distal end. The boom pivots at its base via the superstructure’s portal frame, with angular positioning achieved through wire rope winches or hydraulic actuators to optimize cutting plane alignment. Boom variants include fixed-length and telescoping designs. The bucket-wheel drive module (electric motor, torque-limiting coupling, and gear reducer) is offset-mounted at the boom’s forward section to enable rotational power transfer.

(4) Material Handling System

Comprises sequential components: intake conveyor, surge hopper, and discharge conveyor. Bridge-type excavators incorporate an intermediate transfer conveyor within the bridging structure for extended material routing.

(5) Electrical Propulsion System

Implements grid-powered variable frequency drive (VFD) systems for precision motor speed regulation.

(6) Hydraulic Control System

Predominantly utilizes hydraulic actuators for bucket-wheel boom elevation control and discharge conveyor positioning adjustments.

High Quality Port Bucket Wheel Excavator | |||

Project | unit | Technical specifications | |

Overall dimensions - L×W×H | mm | 21090×4000×5888 | |

track size | mm | 5700×600 | |

Width of track shoe | mm | 600 | |

Track drive hydraulic motor | / | Hydraulic motor+reducer | |

Teack drive hydraulic pump | / | Danvers | |

Hydraulic pump drive motor | kw | 45 | |

Bucket wheel arm length | mm | 8280 | |

Length of discharge arm | mm | 8000+3000 | |

Rated output | m³/h | 900 | |

Bucket wheel diameter | mm | 3600 | |

Bucket wheel speed | r/min | 0-8 | |

Volume of each bucket wheel | m³ | 0.3 | |

Number of buckets | piece | 8 | |

Pitch angle of bucket wheel | ° | 25~-5 | |

Material density | t/m³ | 0.8~1.8 | |

Turning radius of bucket wheel | mm | 10036 | |

Width of reclaiming conveyer belt | mm | 1200 | |

Bucket wheel rotation angle | ° | ±180 | |

Width of discharge conveyer belt | mm | 1000 | |

Length of discharge conveyer belt | mm | 29524 | |

Rotation angle of discharge conveyer belt | ° | ±65 | |

Pitch angle of discharge conveyer belt | ° | 0-16 | |

Max stack height of discharge conveyer belt | mm | 6500 | |

Driving form of telescopic mechanism | / | Hydraulic cylinder | |

Overload protection mode of bucket wheel | / | Automatic | |

Matching motor power | Track travel drive | kW | 45 |

| Bucket wheel swing drive | kW | 75 | |

| Bucket wheel conveyer belt drive | kW | 15*2 | |

| Outfeed conveyer belt drive | kW | 15*2 | |

| Engine power | Track travel drive | kW | 105 |

Company Strength:

Founded in February 2009, Shandong Shante Heavy Industry Machinery Co., Ltd is a natural person wholly-owned enterprise engaged in research and development, production, manufacturing and sales of mechanical equipment in coal mines, water conservancy projects and non-coal mines. With an area of over 10 hectares, the company has four series of more than 20 varieties, mainly including mining electric excavators, mining slag extractors, digging transfer machines, coal unloaders, milling excavators, etc. Its products are widely used in coal and non-coal mines, water conservancy projects, railway construction and tunnel, culvert excavation, loading and unloading, transferring and stacking of railway port cargo. The domestic market covers 28 provinces, municipalities and autonomous regions. The products are exported to Russia, South America, Southeast Asia and Africa, and have served more than 30 countries and regions around the world. After more than ten years of efforts and development, the company has won the fame and become the lead in the domestic mining machinery industry. It has successively won the Certificate of National High-tech Enterprise, the Certificate of Coal Safety and Mine Safety issued by the Anbiao National Center for Mining Products Safety Sign, and has been rated as the Provincial/Municipal Advanced Enterprise, the Enterprise that Honors Contract and Keeps Promise and Provincial Civilized Unit for many years.

In addition, as the New Material Technology Incubation Center, Teaching and Experiment Base and Post-doctoral Innovation Practice Base of Shandong University, the company also acts as the Municipal Enterprise Technology Center and Municipal Key Laboratory. The company has a solid foundation of innovation, leading innovation ability in the industry, excellent service, honesty and trustworthiness, excellent product quality, and hence the continuous improvement of enterprise popularity and reputation is well expected. The annual output of various mining machinery is 3000 sets.

Leave your messages