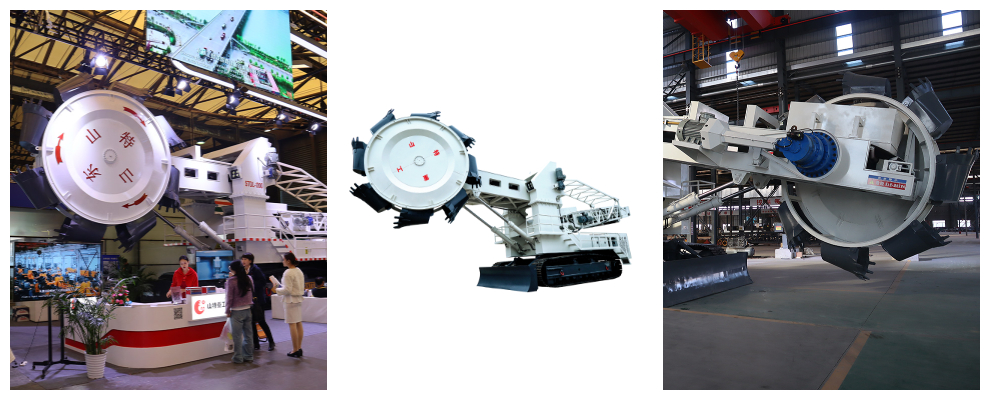

Electric Bucket Wheel Excavator

Product Advantages

High efficiency: The bucket wheel machine has a strong loading capacity, which can load a large amount of materials at one time and transport them to the destination.

Wide range of applications: bucket wheel machine is not only suitable for large coal, ports and other logistics centers, but also suitable for construction sites, metallurgy, chemical industry and other industries handling and drying work.

High efficiency and reliability: bucket wheel machine has efficient operation capacity and transportation system, which can quickly complete a large number of material handling and stacking work.

Product Details

Product Introduction

Enhanced Operational Performance: The bucket wheel system demonstrates robust material intake capacity, enabling consolidated bulk material loading and streamlined transfer processes. Accelerated cargo cycling rates facilitate high-volume task execution within compressed operational timelines, substantially elevating industrial productivity.

Multi-Sector Versatility: Designed for cross-industry deployment, this machinery serves coal logistics hubs, port terminals, construction zones, metallurgical facilities, and chemical processing plants. Its operational flexibility addresses diverse material conveyance, stacking, and specialized drying requirements across multiple industrial workflows.

Uninterrupted Workflow Capability: Engineered for non-stop functionality, the equipment eliminates operational pauses inherent to conventional material-handling systems, ensuring superior continuity and throughput consistency.

Optimized Efficiency & Reliability: Integrated drive mechanisms and precision conveying systems enable rapid bulk material redistribution and accurate stockpile formation. An advanced monitoring framework with real-time diagnostics enhances operational integrity, equipment safety, and anomaly detection responsiveness. Simplified Maintenance Architecture: Modular component design streamlines repair protocols and part replacement workflows, effectively minimizing lifecycle maintenance expenditures.

Intuitive Operational Interface: The system features logic-based controls requiring minimal operator training. Mastery of core command sequences, interface navigation, and adherence to safety protocols ensures stable, high-efficiency performance without specialized technical expertise.

Project | Unit | STDL-500 | STDL-1000 | STDL-1600 | STDL-2600 |

| Overall dimensions (L × W × H) | mm | 17100×3600×4680 | 21100×4000×5900 | 25000×5000×72800 | 30000×5900×8300 |

| Bucket wheel diameter | mm | 3000 | 3600 | 4500 | 5800 |

| Bucket wheel arm length | mm | 6980 | 8280 | 9280 | 11280 |

| Bucket wheel volume | m³/pc | 0.2 | 0.3 | 0.4 | 0.42 |

| Number of buckets | piece | 8 | 8 | 10 | 14 |

| Rated output | m³/h | 500 | 1000 | 1600 | 2600 |

| Material density | t/m³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ |

| Length of discharge arm | mm | 7000+3000 | 8900+3400 | 9000+4000 | 9000+5000 |

| Length of discharge conveyor | mm | 25000 | 33375 | 33375 | 36000 |

| Maximum stack height of discharge conveyor | mm | 5500 | 6500 | 7000 | 8000 |

| Power | kW | 200 | 295 | 420 | 509 |

Company Profile

Shandong Shante Heavy Industry Machinery Co., Ltd, established in February 2009, is a wholly-owned enterprise by a natural person specializing in the R&D, production, manufacturing, and sales of mechanical equipment for coal mines, water conservancy projects, and non-coal mines. Spanning over 10 hectares, the company offers four product series comprising more than 20 varieties, including mining electric excavators, mining slag extractors, digging transfer machines, coal unloaders, and milling excavators. Its products are extensively utilized across coal/non-coal mining operations, water conservancy projects, railway construction, tunnel and culvert excavation, as well as cargo loading, transferring, and stacking in railway ports.

Domestically, the company serves markets in 28 provinces, municipalities, and autonomous regions, while its global footprint extends to Russia, South America, Southeast Asia, Africa, and over 30 countries/regions worldwide. Through over a decade of dedicated development, the company has emerged as an industry leader in domestic mining machinery, earning recognition as a National High-tech Enterprise and securing coal/mine safety certifications from the Anbiao National Center for Mining Products Safety Sign. It has been repeatedly honored as a Provincial/Municipal Advanced Enterprise, a Contract-Compliant & Trustworthy Enterprise, and a Provincial Civilized Unit.

The company also serves as the New Material Technology Incubation Center, Teaching & Experiment Base, and Postdoctoral Innovation Practice Base for Shandong University, in addition to operating as a Municipal Enterprise Technology Center and Municipal Key Laboratory. With robust innovative capabilities, industry-leading R&D expertise, premium services, and unwavering commitment to integrity and product quality, the company continues to enhance its reputation and market presence. Its annual production capacity reaches 3,000 units of mining machinery.

Leave your messages