Best Price Bucket Wheel Stacker Reclaimer For Port

Product Advantages

High efficiency: The bucket wheel machine has a strong loading capacity, which can load a large amount of materials at one time and transport them to the destination.

Wide range of applications: bucket wheel machine is not only suitable for large coal, ports and other logistics centers, but also suitable for construction sites, metallurgy, chemical industry and other industries handling and drying work.

Strong ability of continuous operation: bucket wheel machine adopts continuous operation mode without shutdown, which has greater advantages compared with traditional loading and unloading machinery.

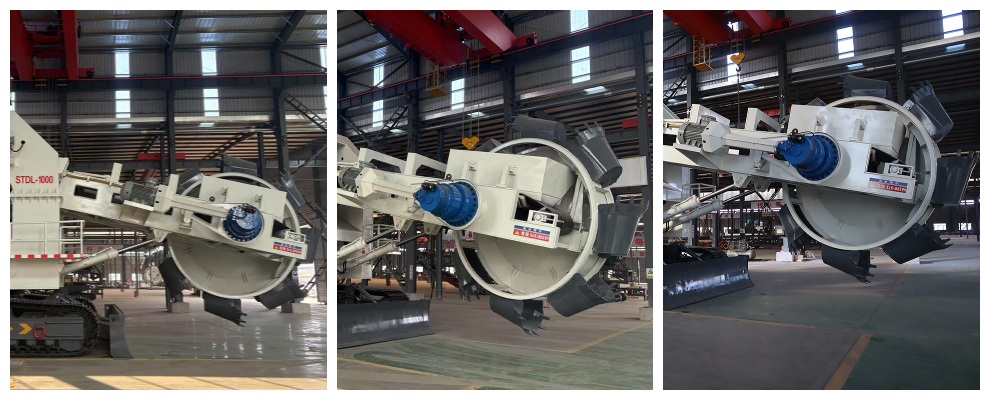

Product Details

Product Introduction

Operational Excellence: The bucket wheel stacker-reclaimer demonstrates superior material throughput capacity, enabling bulk commodity management across extended operational cycles. Enhanced operational speeds allow rapid cycle completion for high-volume workflows, optimizing resource utilization and throughput efficiency.

Cross-Industry Functionality: Engineered for multipurpose functionality, the system addresses material management needs in varied environments including energy distribution hubs, maritime logistics centers, infrastructure development sites, and process industries requiring precision stockpile organization. Its adaptive design supports complex spatial and volumetric demands across sectors.

Non-Stop Productivity: Built for continuous duty cycle execution, the equipment maintains consistent operational rhythms with minimized interruptions, outperforming conventional material handling systems in sustained output stability and process continuity.

Intelligent Engineering: Integrated drive dynamics and precision motion control systems ensure synchronized material flow and accurate placement. Smart monitoring interfaces with embedded diagnostics enhance operational transparency, enabling preemptive anomaly detection and safety protocol enforcement for mission-critical reliability.

Maintenance Efficiency: Component accessibility via modular construction architecture simplifies servicing protocols and rapid part interchangeability, substantially reducing equipment downtime lifecycle costs.

Operational Simplicity: The ergonomic control architecture with visual workflow guidance requires reduced operator training investment. Mastery of core operational principles and safety compliance ensures peak performance accessibility without specialized expertise.

Project | Unit | STDL-500 | STDL-1000 | STDL-1600 | STDL-2600 |

| Overall dimensions (L × W × H) | mm | 17100×3600×4680 | 21100×4000×5900 | 25000×5000×72800 | 30000×5900×8300 |

Bucket wheel diameter | mm | 3000 | 3600 | 4500 | 5800 |

Bucket wheel arm length | mm | 6980 | 8280 | 9280 | 11280 |

Bucket wheel volume | m³/pc | 0.2 | 0.3 | 0.4 | 0.42 |

Number of buckets | piece | 8 | 8 | 10 | 14 |

Rated output | m³/h | 500 | 1000 | 1600 | 2600 |

Material density | t/m³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ |

Length of discharge arm | mm | 7000+3000 | 8900+3400 | 9000+4000 | 9000+5000 |

Length of discharge conveyor | mm | 25000 | 33375 | 33375 | 36000 |

Maximum stack height of discharge conveyor | mm | 5500 | 6500 | 7000 | 8000 |

Power | kW | 200 | 295 | 420 | 509 |

Corporate Overview

Established in 2009, Shandong Shante Heavy Industry Machinery Co., Ltd is a privately held enterprise specializing in the innovation, production, and global distribution of industrial equipment tailored for mineral extraction, hydraulic engineering, and diversified mining applications. Headquartered in a state-of-the-art manufacturing facility, the company delivers a comprehensive portfolio of over 20 advanced machinery solutions, spanning electrically driven excavation systems, material handling units, and specialized coal processing equipment. These technologies are deployed across coal and non-coal mining operations, infrastructure development projects, and logistics hubs, enhancing efficiency in cargo management and industrial workflows.

With a robust domestic network and international reach extending to markets in South America, Africa, Southeast Asia, and beyond, Shante has cemented its leadership in China’s heavy machinery sector through sustained innovation and strategic growth. Recognized as a National High-Tech Enterprise and holder of industry safety certifications, the company has earned repeated accolades for operational integrity, including provincial honors for contractual compliance and corporate excellence.

As a collaborative partner in technological advancement, Shante serves as an innovation hub for Shandong University, hosting academic research initiatives, experimental training programs, and postdoctoral development projects. Its municipal-level R&D centers and dedicated laboratories underscore a commitment to cutting-edge engineering and product reliability. Renowned for ethical business practices, customer-centric service, and durable machinery performance, the company continues to elevate its industry standing while maintaining scalable production capabilities to meet global demand.

Leave your messages