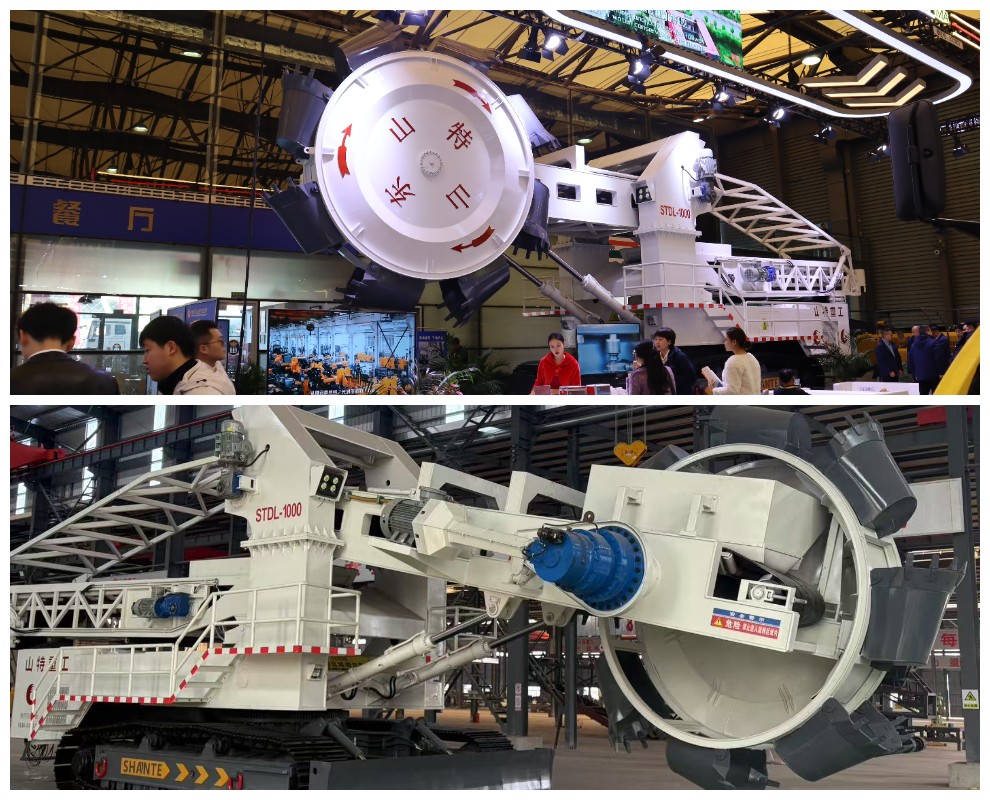

Bucket Wheel Stacker

Product Advantages

High efficiency: The bucket wheel machine has a strong loading capacity, which can load a large amount of materials at one time and transport them to the destination. Its loading and unloading speed is fast, can complete a large number of handling tasks in a short time, and significantly improve production efficiency.

Wide range of applications: bucket wheel machine is not only suitable for large coal, ports and other logistics centers, but also suitable for construction sites, metallurgy, chemical industry and other industries handling and drying work.

Strong ability of continuous operation: bucket wheel machine adopts continuous operation mode without shutdown, which has greater advantages compared with traditional loading and unloading machinery.

Product Details

Product Introduction

High Efficiency: The bucket wheel machine boasts robust loading capacity, enabling it to handle large quantities of materials in a single operation and transport them efficiently to their destination. Its rapid loading and unloading speeds allow for the completion of substantial handling tasks within short timeframes, significantly boosting productivity.

Wide Range of Applications: Bucket wheel machines are not only ideal for large-scale logistics hubs such as coal terminals and ports but are also well-suited for material handling and drying operations in industries like construction, metallurgy, and chemical processing. Their adaptability spans diverse working environments.

Strong Continuous Operation Capability: Utilizing a continuous operational mode without requiring shutdowns, bucket wheel machines outperform traditional loading and unloading machinery in terms of sustained productivity.

High Efficiency and Reliability: Equipped with advanced operational and transportation systems, bucket wheel machines can swiftly execute large-scale material handling and stacking tasks. Integrated control and monitoring systems enable real-time machine status tracking, enhancing operational reliability and safety.

Convenient Maintenance: Featuring a modular design, bucket wheel machines simplify maintenance and component replacement, reducing overall operational and upkeep costs.

User-Friendly Operation: The bucket wheel machine’s operation is straightforward. With basic training to familiarize users with control interfaces, button functions, and the equipment’s working principles and workflows, operators can efficiently manage the machine. Minimal technical expertise is required, and adherence to safety protocols ensures stable, high-performance operation.

Project | Unit | STDL-2000 |

| Overall dimensions (L × W × H) | mm | 30000×5900×8300 |

| Bucket wheel diameter | mm | 5800 |

| Bucket wheel arm length | mm | 11280 |

| Bucket wheel volume | m³/pc | 0.42 |

| Number of buckets | piece | 14 |

| Rated output | m³/h | 2000 |

| Material density | t/m³ | (0.8-1.8) ×10³ |

| Length of discharge arm | mm | 9000+5000 |

| Length of discharge conveyor | mm | 36000 |

| Maximum stack height of discharge conveyor | mm | 8000 |

| Power | kW | 509 |

| Conveyor specification | mm | 1400 |

| Conveyor speed | m/s | 2.8 |

| Equipment weight | T | 168 |

| Bucket wheel speed(rpm) | r/s | 6.8 |

| Travelling Speed. | m/min | 20 |

| Luffing angle | ° | ±18 |

| Slew angle | ° | 135 |

Leave your messages