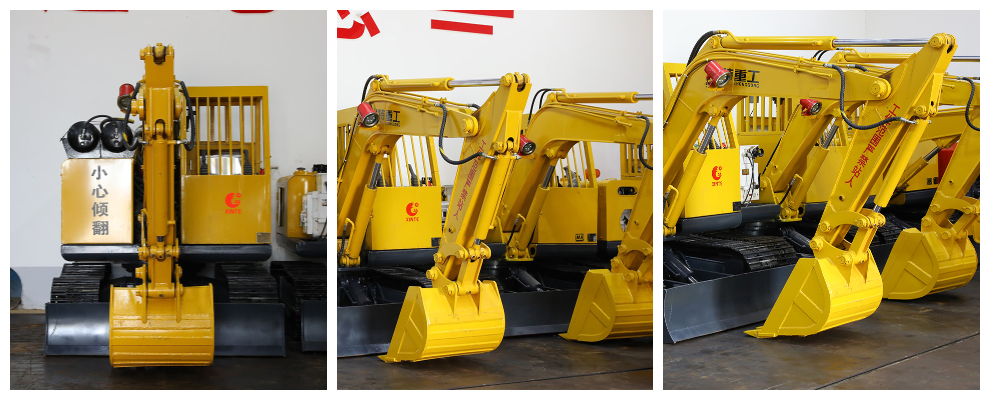

Customizable Diesel Excavator For Tunnel

Product Advantages:

The machine is suitable for rock loading, bottom cleaning and excavation of frozen soil in coal mines, metal mines, non - metallic mines, shafts, inclined shafts and flat tunnels. Compared with the traditional manual bottom cleaning, the use of the machine greatly saves labor costs while improving the operation efficiency and improving the working environment.

The operator works under the protection of the cab, which is conducive to safe production. Compared with the traditional diesel - powered mini excavator, due to the use of electro - hydraulic system, this machine has the characteristics of energy saving, low noise, no exhaust gas pollution and high efficiency, and is more suitable for underground use.

The machine has compact structure, small size and small sub - assembly parts, which is convenient for vertical use. This machine adopts the minimum swing structure, and its tail will not exceed the width of the car when the body is rotated, so it is more suitable for the narrow space underground.

Product Details

Product Introduction:

Our Customizable Diesel Excavator For Tunnel tailored for underground mining applications, this hydraulic excavator specializes in roadway maintenance, drainage trench excavation, coal slag removal, debris clearance, and surface leveling. Constructed with heavy-duty, corrosion-resistant components to endure harsh subterranean conditions, its compact design delivers exceptional agility in tight spaces. The machine achieves seamless 360° rotation within confined cross-sectional areas while executing versatile tasks such as excavation, grading, sidewall digging, rock breaking, and material loading. It is adept at managing demanding operations, including rugged trenching, coal residue disposal, waste elimination, and roadway preparation.

The upper structure supports unrestricted 360° rotation, enabling efficient excavation and material crushing beneath conveyor systems. Its articulated boom allows unimpeded digging and crushing across a full operational range at adjustable heights within mine passages. An integrated adjustable front blade stabilizes the machine during tasks and aids in precise surface grading. Hydraulic lines flanking the boom are shielded by spring-reinforced armored sleeves, preventing damage in abrasive working environments.

Equipped with an intelligent load-sensing hydraulic system, the excavator dynamically adjusts pump output to match real-time operational demands while maintaining precise control over load movement and speed. This innovation embodies the forefront of hydraulic technology in modern construction machinery.

The system incorporates an air-start mechanism for reliable ignition in low-temperature conditions and an advanced water scrubber exhaust purification system. This emission control solution neutralizes toxic engine byproducts into harmless gases, drastically reducing airborne pollutants and fostering safer underground air quality.

Project | Unit | MWC6/0.3L | ||

| The structural form of the working body | / | Three - section arms | ||

| Auxiliary arm rotation angle | ° | ±90° | ||

| Motor Power | Kw | 105 | ||

Hydraulic system | Rated pressure | mpa | 23.5 | |

| Main pump flow | L/min | 130 | ||

| The type of hydraulic pump | / | Variable displacement pumps | ||

| The driving way of walking | / | Intergrated hydraulic motor reducer drive | ||

Walking mechanism | Walking form | / | Crawler traveling | |

| Specific pressure to ground | mpa | ≤0.1 | ||

| Traveling Speed | km/h | 0-3.5 | ||

| Ground clearance | mm | 300 | ||

| Climbing ability | ° | 15 | ||

| Swing angle | ° | 360 | ||

| Swing speed | r/min | 0-10 | ||

| Crawler type | / | steel crawler | ||

| Full crawler length | mm | 2450 | ||

| crawler width | mm | 400 | ||

Bucket loading | Bucket capacity | m³ | 0.3 | |

| Digging radius | mm | 4800 | ||

| Max elevation arm height | mm | 5200 | ||

| Max discharge height | mm | 3830 | ||

| Max digging depth | mm | 2500 | ||

| Tail swing radius | mm | 1800 | ||

| Bucket digging force | KN | 35 | ||

| Nominal working pressure | mpa | 9-12 | ||

hydraulic breaker | operating flow | L/min | 25-50 | |

| Impact frequency | rpm | 600-1100 | ||

| Impact energy | J | 350 | ||

| Suitable Brazing tools specification | mm | 53 | ||

| Noise | dB(A) | ≤120 | ||

| Dozer blade width*H | mm | 1900×370 | ||

| Overall form factor(L*W*H) | mm | 3750×1900×2350 | ||

| Weight | t | 6.2 | ||

Company Strength:

Founded in February 2009, Shandong Shante Heavy Industry Machinery Co., Ltd is a natural person wholly-owned enterprise engaged in research and development, production, manufacturing and sales of mechanical equipment in coal mines, water conservancy projects and non-coal mines. With an area of over 10 hectares, the company has four series of more than 20 varieties, mainly including mining electric excavators, mining slag extractors, digging transfer machines, coal unloaders, milling excavators, etc. Its products are widely used in coal and non-coal mines, water conservancy projects, railway construction and tunnel, culvert excavation, loading and unloading, transferring and stacking of railway port cargo. The domestic market covers 28 provinces, municipalities and autonomous regions. The products are exported to Russia, South America, Southeast Asia and Africa, and have served more than 30 countries and regions around the world. After more than ten years of efforts and development, the company has won the fame and become the lead in the domestic mining machinery industry. It has successively won the Certificate of National High-tech Enterprise, the Certificate of Coal Safety and Mine Safety issued by the Anbiao National Center for Mining Products Safety Sign, and has been rated as the Provincial/Municipal Advanced Enterprise, the Enterprise that Honors Contract and Keeps Promise and Provincial Civilized Unit for many years.

In addition, as the New Material Technology Incubation Center, Teaching and Experiment Base and Post-doctoral Innovation Practice Base of Shandong University, the company also acts as the Municipal Enterprise Technology Center and Municipal Key Laboratory. The company has a solid foundation of innovation, leading innovation ability in the industry, excellent service, honesty and trustworthiness, excellent product quality, and hence the continuous improvement of enterprise popularity and reputation is well expected. The annual output of various mining machinery is 3000 sets.

Leave your messages