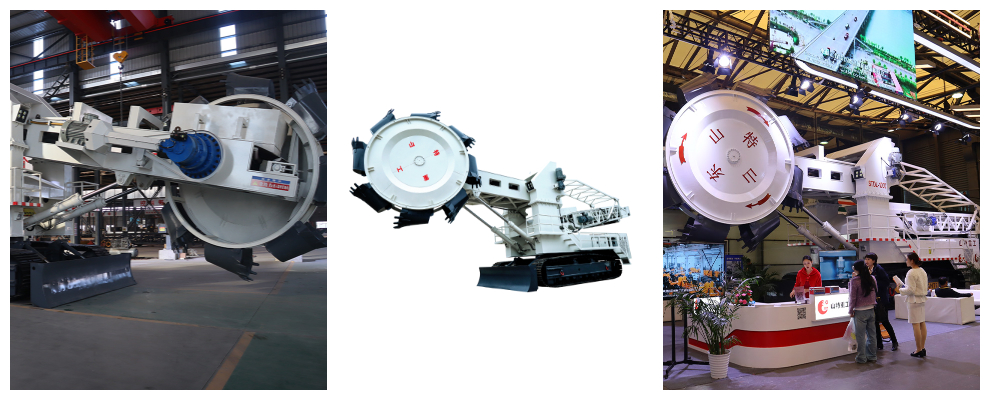

Hot selling Bucket Wheel Stacker Reclaimer For Port

Product Advantages:

High Efficiency: The bucket wheel stacker reclaimer boasts robust loading capacity, enabling bulk material handling and transportation in a single operation.

Versatile Applications: This machine is engineered for diverse industrial environments, including large-scale coal terminals, port logistics hubs, construction sites, metallurgical plants, chemical facilities, and other sectors requiring material handling and stacking operations.

Streamlined Maintenance: Featuring modular construction, the machine simplifies maintenance workflows and component replacement, significantly reducing operational downtime and long-term upkeep costs.

Product Details

Product Introduction:

Hot selling Bucket Wheel Stacker Reclaimer For Port.

High Efficiency: The bucket wheel stacker reclaimer features exceptional loading capacity, facilitating large-scale material handling and transportation in a single cycle. Its accelerated loading/unloading rates enable the completion of extensive tasks within compressed timelines, significantly enhancing overall productivity.

Versatile Applications: Designed for adaptability, this machine serves a wide array of industrial settings—from coal terminals and port logistics complexes to construction zones, metallurgical facilities, chemical plants, and sectors demanding precision material stacking. Its versatility covers a comprehensive range of operational requirements.

Uninterrupted Continuous Operation: Engineered for relentless performance, the bucket wheel stacker reclaimer ensures uninterrupted operation with zero downtime, surpassing traditional loading/unloading machinery in both efficiency and operational consistency.

Optimized Performance & Reliability: Incorporating a high-performance drive system and precision-engineered conveyor technology, the machine guarantees rapid material transfer and meticulous stacking. Advanced real-time monitoring through cutting-edge control and diagnostic systems elevates operational reliability, safety, and proactive fault resolution.

Streamlined Maintenance: With its modular design, the machine facilitates streamlined maintenance procedures and swift component replacements, drastically minimizing operational disruptions and long-term maintenance expenditures.

User-Friendly Operation: User-centric controls and an intuitive interface demand minimal training. Proficiency in fundamental operations, workflow mechanics, and compliance with safety guidelines ensures consistent, high-efficiency performance—eliminating the need for specialized technical skills.

Hot selling Bucket Wheel Stacker Reclaimer For Port | |||

Project | unit | Technical specifications | |

Overall dimensions - L×W×H | mm | 21090×4000×5888 | |

track size | mm | 5700×600 | |

Width of track shoe | mm | 600 | |

Track drive hydraulic motor | / | Hydraulic motor+reducer | |

Teack drive hydraulic pump | / | Danvers | |

Hydraulic pump drive motor | kw | 45 | |

Bucket wheel arm length | mm | 8280 | |

Length of discharge arm | mm | 8000+3000 | |

Rated output | m³/h | 900 | |

Bucket wheel diameter | mm | 3600 | |

Bucket wheel speed | r/min | 0-8 | |

Volume of each bucket wheel | m³ | 0.3 | |

Number of buckets | piece | 8 | |

Pitch angle of bucket wheel | ° | 25~-5 | |

Material density | t/m³ | 0.8~1.8 | |

Turning radius of bucket wheel | mm | 10036 | |

Width of reclaiming conveyer belt | mm | 1200 | |

Bucket wheel rotation angle | ° | ±180 | |

Width of discharge conveyer belt | mm | 1000 | |

Length of discharge conveyer belt | mm | 29524 | |

Rotation angle of discharge conveyer belt | ° | ±65 | |

Pitch angle of discharge conveyer belt | ° | 0-16 | |

Max stack height of discharge conveyer belt | mm | 6500 | |

Driving form of telescopic mechanism | / | Hydraulic cylinder | |

Overload protection mode of bucket wheel | / | Automatic | |

Matching motor power | Track travel drive | kW | 45 |

| Bucket wheel swing drive | kW | 75 | |

| Bucket wheel conveyer belt drive | kW | 15*2 | |

| Outfeed conveyer belt drive | kW | 15*2 | |

| Engine power | Track travel drive | kW | 105 |

Company Strength:

Founded in February 2009, Shandong Shante Heavy Industry Machinery Co., Ltd is a natural person wholly-owned enterprise engaged in research and development, production, manufacturing and sales of mechanical equipment in coal mines, water conservancy projects and non-coal mines. With an area of over 10 hectares, the company has four series of more than 20 varieties, mainly including mining electric excavators, mining slag extractors, digging transfer machines, coal unloaders, milling excavators, etc. Its products are widely used in coal and non-coal mines, water conservancy projects, railway construction and tunnel, culvert excavation, loading and unloading, transferring and stacking of railway port cargo. The domestic market covers 28 provinces, municipalities and autonomous regions. The products are exported to Russia, South America, Southeast Asia and Africa, and have served more than 30 countries and regions around the world. After more than ten years of efforts and development, the company has won the fame and become the lead in the domestic mining machinery industry. It has successively won the Certificate of National High-tech Enterprise, the Certificate of Coal Safety and Mine Safety issued by the Anbiao National Center for Mining Products Safety Sign, and has been rated as the Provincial/Municipal Advanced Enterprise, the Enterprise that Honors Contract and Keeps Promise and Provincial Civilized Unit for many years.

In addition, as the New Material Technology Incubation Center, Teaching and Experiment Base and Post-doctoral Innovation Practice Base of Shandong University, the company also acts as the Municipal Enterprise Technology Center and Municipal Key Laboratory. The company has a solid foundation of innovation, leading innovation ability in the industry, excellent service, honesty and trustworthiness, excellent product quality, and hence the continuous improvement of enterprise popularity and reputation is well expected. The annual output of various mining machinery is 3000 sets.

Leave your messages